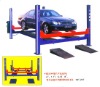

- Car Lifts[9]

- Wheel Alignment[10]

- Tire Changers[1]

- Other Vehicle Equipment[10]

- Other Vehicle Tools[10]

- Other Car Care Equipment[10]

- Tire Repair Tools[1]

- Contact Person : Ms. Feng Olive

- Company Name : Guangzhou Lawrence Automobile Science & Technology Co., Ltd.

- Tel : 86-20-86328363

- Fax : 86-20-86318680

- Address : Guangdong,Guangzhou,No. 2 Middle Road of Caozhuang Industry Zone, Taihe town, Baiyun district, Guangzhou, China

- Country/Region : China

- Zip : 510540

Lawrenfe excellent Car lift, high performance car maintainence,3D wheel aligner system, auto testing machinery

X3D Wheel Alignment system, 3D Wheel Aligner, Intelligent Wheel Alignment, garage equipment,Intelligent Wheel Alignment, wheel aligner, garage equipment,Laser machine

Configuration:

Exquisite Movable Small Cabinet

Intelligent Auto Lifting Pole

HP Computer

27' LCD monitor

Unique Target Disks

Deluxe Holding Tire Clamps

High Definition Camera

Steering Wheel Lock

Brake Lock

Wedge-shaped Pads

Turntables

Transition Blocks of Turntables

Canon Printer

Outstanding Functions

1. IAA1: During operating, the cameras track the position of the vehicle and adjust to the corresponding height automatically.

2. 3D Measurement: The 3D measuring techniques which is based on real running surface of wheels is more specific and precision.

3. Shooting System: Composed of high-performance cameras and four target disks, the camera system can measure the vehicle’s running posture vividly.

4. Target Disk: The solid-state target disks made of special materials are sturdy and durable without electronic components.

5. Pushing Measurement: None of any wheel compensation is needed. Only one pushing can complete the measurement.

6. 3D Max System: The unique visual 3D max dynamic measurement system is real and vivid.

7. Calibration System: Only one simple calibration is needed after the initial installation without any repetitive calibration following.

Advantages of 3D Wheel Aligners

The target disks are not composed of the electronic components used in traditional wheel alignment. The problems caused by the influence of the electronic components are eliminated.There is no need to do complex wheel compensation for the wheel theoretic plane. Only one pushing measurement is needed to complete the precision measuring in order to shorten testing time.3D data alalysis

Principles

The corresponding datum plane and driving central line for calculating are constructed by the centre of four wheels got by the four target disks. Then according to the position of each disk in the plane and central line, the parameters of wheel alignment can be figured out. Therefore, measurement deviation due to the non-horizontal vehicle plane and lifting platform during the measurement can be avoided.

Principles of V3D System

During operating, users can adjust the height of vehicles according to their requirements. And the IAA1 system can automatically calculate and adjust the cameras to the corresponding height. No manual work will intervene in this process. There is no influence on measurement results.

Schematic Illustration of BCC

BCC: After initial installation, only one simple calibration is needed, the best measuring results can be achieved. And there is no need for repetitive calibration.

Original Standard Database

This database contains the original datum and information of over 20 thousand car models.

Measurement items | Accuracy | Measurement range |

Show Precision | 1´/ | |

Camber | ±2´ | ±15° |

Caster | ±3´ | ±26° |

Kingpin Inclination | ±3´ | ±26° |

Toe-in & Toe-out | ±2´ | ±20° |

Set back | ±2´ | ±5° |

Thrust angle | ±2´ | ±5° |

Lawrenfe excellent Car lift, high performance car maintainence,3D wheel aligner system, auto testing machinery